Introduction to Injection Molding

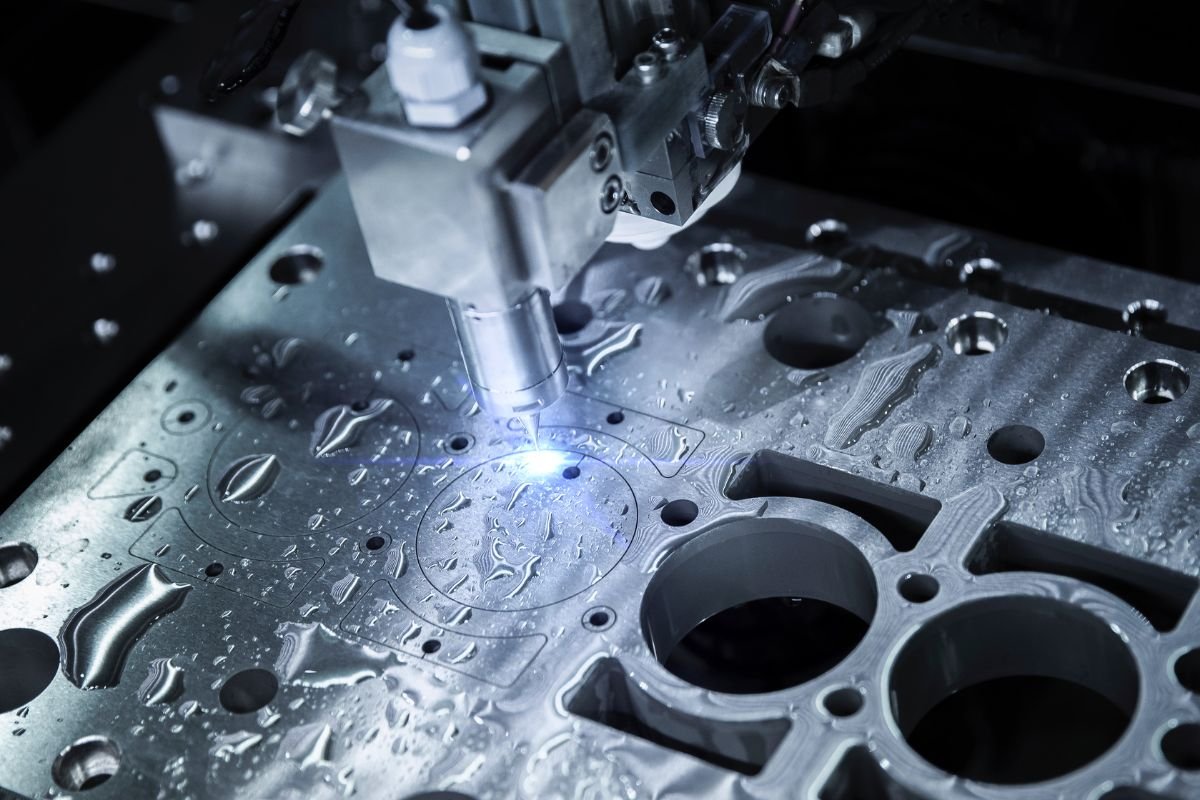

Injection molding is a widely utilized manufacturing process that plays a crucial role in the production of plastic components across various industries. This method involves injecting molten material into a mold, where it cools and solidifies into the desired shape. The significance of injection molding lies in its ability to produce high volumes of complex parts with precision and consistency, making it an essential process for businesses seeking efficiency and cost-effectiveness in production.

One major advantage of injection molding is its versatility with a variety of materials. Commonly used materials include thermoplastics and thermosetting plastics, each offering distinct benefits based on the application. Thermoplastics, for instance, can be reprocessed multiple times without degrading, while thermosetting plastics provide strong and durable components suitable for high-heat applications. This flexibility in material choice allows companies to select the optimal options tailored to their specific needs.

The applications for injection molding are vast, spanning multiple sectors, including automotive, consumer goods, electronics, and medical devices. Businesses in these industries frequently opt for this manufacturing process due to its ability to reduce labor costs, minimize waste, and enhance production speed. Furthermore, injection molding enables the creation of intricate designs with tight tolerances, which is often unattainable with other manufacturing processes.

In summary, the injection molding process not only enhances production capabilities but also supports innovation through design flexibility and material adaptability. As companies continue to embrace this method, the need for dependable injection molding companies in Texas becomes increasingly critical, ensuring that they can source the necessary components while maintaining quality and efficiency. Whether for small-scale projects or large-volume production runs, understanding the fundamentals of injection molding underscores its importance in modern manufacturing.

Criteria for Selecting Injection Molding Companies

When evaluating injection molding companies in Texas, several critical criteria should guide your decision-making process. These factors ensure that you partner with a company capable of meeting your specific manufacturing requirements.

Experience is one of the foremost factors to consider. Companies with several years in the industry typically possess a depth of knowledge and skills that can significantly impact the quality of your product. These companies are likely familiar with a wide array of materials and injection molding techniques, which can help in achieving precision and efficiency.

Next, it is essential to assess the capabilities of the injection molding companies you are considering. Look for firms that can handle the specific type of projects you require, whether that involves complex geometries or high-volume production. Advanced capabilities such as multi-material molding or rapid prototyping can also be significant advantages, especially for specialized projects.

Certifications and compliance with industry standards cannot be overlooked. Companies that hold relevant certifications demonstrate a commitment to quality and safety. This aspect is especially important in sectors such as medical or automotive manufacturing, where adherence to regulatory requirements is critical.

Customer service is another vital criterion. A responsive and knowledgeable team can make a significant difference throughout the project lifecycle. The best injection molding companies in Texas prioritize communication and provide clear timelines, helping to foster a strong partnership.

Lastly, technological advancement is increasingly important in the ever-evolving landscape of manufacturing. Companies that invest in the latest equipment and software are better positioned to deliver high-quality products efficiently. By evaluating these key criteria, businesses can make informed decisions when selecting from among the top 10 injection molding companies in Texas.

Top 10 Injection Molding Companies in Texas

Texas is home to numerous injection molding companies that cater to a diverse range of industries. The following is a curated list of ten notable injection molding companies in Texas, providing insight into their history, mission, and specialties.

1. Cortech Engineering – Established in 1991, Cortech Engineering focuses on custom injection molding and precision components. Their mission is to deliver high-quality solutions that meet their clients’ specifications. They specialize in medical, automotive, and consumer products.

2. RBM Technologies – This company has cultivated a reputation for its innovative approach to injection molding since 1999. RBM Technologies prides itself on molding complex geometries and focuses on the advancement of technology in the plastics industry.

3. Vantage Plastics – With over 30 years of experience, Vantage Plastics is known for its commitment to sustainability and quality. They specialize in custom molds for various sectors including packaging, automotive, and electronics.

4. A&R Tarpaulins – Founded in the early 2000s, A&R Tarpaulins offers a wide range of injection molded products predominantly for agricultural and industrial applications. Their mission emphasizes durability and customer satisfaction.

5. Texas Injection Molding – A relatively new contender in the market, Texas Injection Molding specializes in high-volume production runs while maintaining stringent quality controls. Their expertise ranges from consumer goods to complex industrial components.

6. Decatur Plastics – Established in the 1980s, Decatur Plastics has built a strong reputation for its ability to create custom molds for various plastic applications. Their dedication to innovation drives their operations.

7. Matthews Specialty Vehicles – Although best known for manufacturing specialty vehicles, Matthews also engages in injection mold production. Their commitment to quality and detail sets them apart in the competitive landscape.

8. Rampart Plastics – Founded in the late 1990s, Rampart Plastics is committed to providing engineering solutions and mold design services for the medical and automotive industries. Their focus remains on precision and efficiency.

9. ProMold – As a leader among injection molding companies in Texas, ProMold specializes in custom plastic parts for various industries. Their innovative design and engineering capabilities make them a trusted partner.

10. Advanced Plastic Solutions – The final entry on our list, Advanced Plastic Solutions, is dedicated to sustainable practices and high-quality molded products. Their innovative solutions cater to multiple sectors, including consumer products and medical devices.

These ten injection molding companies in Texas exemplify the region’s robust capabilities in the plastics manufacturing sector. Each company offers unique strengths that can be leveraged for various business needs in the industry.

Conclusion and Industry Outlook

As highlighted throughout this blog post, the role of injection molding companies in Texas is imperative to numerous sectors including automotive, consumer goods, and healthcare. These companies not only contribute to the local economy but also enhance innovation and efficiency across industries. Texas, being home to a multitude of seasoned injection molding companies, stands at the forefront of manufacturing excellence in the United States. The expertise demonstrated by these companies, complemented by their strategic geographic positioning, allows them to serve a broad spectrum of clients effectively.

Looking ahead, the injection molding industry is poised for transformative changes. The growing demand for lightweight materials and more intricate designs indicates a shift towards advanced methodologies and technologies. Furthermore, sustainability is becoming a core focus. It is anticipated that injection molding companies in Texas will increasingly adopt eco-friendly practices and materials, aligning with global sustainability goals. Innovations such as bio-based plastics and energy-efficient machinery are likely to become standard practices among leading manufacturers.

Technological advancements also play a significant role in shaping the future of this industry. The integration of automation and smart manufacturing technologies can enhance production efficiency, reduce costs, and improve overall product quality. Companies that utilize these innovations will have a competitive edge in delivering tailor-made solutions that meet diverse client requirements.

In conclusion, as the demand for sophisticated and eco-friendly solutions continues to rise, partnering with the right injection molding companies in Texas is vital for businesses seeking to stay relevant and competitive in the market. The synergy of technological advancements, sustainability, and innovative practices promises a robust future for the injection molding industry, making it an exciting field to watch for upcoming opportunities and developments.